1. How do I begin the process?

All we need to begin is a completed design planner. Please use the link to access the design planner and just sent it back to us when completed.

2. What is the professional design services fee?

Ccd offers complimentary design planning. You will receive free 3d renderings of your space as well as your direct to you pricing.

3. What is the turnaround time once a design planner is submitted?

We will assign the completed design planner to one of our award winning design team members immediately. The typical turnaround time on a complete design is 3 to 5 business days depending on current workload.

4. How do I determine which manufacturer to work with?

Give us a call and we can help direct you to an approriate match. Inspirational pictures are helpful as well to determine the “look” you are trying to achieve, as well as to help point you towards the best manufacturer to use. You can also go directly to each manufacturers website from the links on the bottom of our home page

5. What is the average price of cabinetry?

This is one of those “loaded” questions, and is really difficult to use a “blanket” amount. In the old days you could figure on rough linear foot price for cabinetry, but with today’s options of door styles, multiple specie of material, man made materials, and endless finish options, we would be doing our clients a disservice to just “shoot out” a number. All of our cabinet lines will represent different options and price levels, your ccd designer will be able to match you up with the line that best fits your needs and expectations.

6. How do I order custom cabinetry?

You and your CCD designer will work together to revise and refine you’re plan to your satisfaction. At this point you will be forwarded a final design binder to review and return to get the order submitted

7. After I order my cabinets, how long before they arrive?

All of our cabinetry lines are produced when ordered; they are not sitting on a shelf, or rta (ready to assemble) cabinets. The typical lead time for custom cabinetry is 6-8 weeks depending on type of cabinetry ordered (for example, inset cabinetry, or cabinetry with specialty finishes will increase the lead time)

8. What form of payment do you accept for custom cabinetry purchases?

We accept all major credit cards (except amex), as well as direct ach or wire transfers

9. How will my cabinets arrive and, will I have to go pick them up somewhere?

All of our cabinetry will be shipped via the manufacturers logistics partners and arrive at a local delivery agent in your area. This local delivery agent will then contact you to arrange a home delivery date and time, no need to rent that moving van!

10. What do I do if my cabinets arrive damaged?

Please contact CCD as soon as possible so that we may work with the manufacturer to get you the needed items as quickly as possible. Warranty orders will always be moved to the “front of the line” with the manufacturers to minimize your down time. All of the manufacturers CCD works with use their preferred shipping partners to minimize freight damage. Ltl carriers are used only in extreme circumstances. All damages must be reported to ccd in a timely fashion per the design approval packet.

11. What if my cabinets do not fit?

If the cabinetry you receive is an error on the part of the manufacturer, ccd will immediately request warranty no-charge replacement(s). This will also include any shipping charges.

12. Why are there so many places that sell cabinets?

It does seem like every retailer that sells flooring, countertops, appliances, etc. are in the cabinet “business”. This may work for some retailers, but CCD focuses solely on supplying high quality cabinetry combined with in-house design services to deliver the end result our clients are expecting.

13. Why do I need a cabinet “designer”?

A true qualified designer will help you realize your vision, improve functionality, and may actually reduce costs with creative ways to maintain design integrity while lowering cost.

14. The cabinet line I am looking at is made with a “plywood” box, that means it is high quality correct?

This is a tricky one. While plywood is the preferred choice of most installers and consumers, but that does not mean the overall quality will meet your expectations. Most imported cabinets will “check” this box, but the difference between imported plywood and North American plywood is substantial. CCD would suggest a North American “furniture board” (also called particle board, however furniture board used in cabinet construction is much higher quality than what you would find in your big box stores) over an imported plywood.

15. Why do I need to work with a “custom cabinet” manufacturer?

Working with a custom or semi-custom cabinet manufacturer will allow your designer to better fit your space since a custom or semi-custom manufacturer will offer many more choices with regard to sizes and cabinetry options. This allows for a true “custom” design without having to work within the limitations a “stock” cabinetry line may offer.

16. The local “custom” cabinetry maker builds cabinets on site, then has the painter paint, is this good?

This may sound like a good practice, but is actually anything but. A cabinet built on site without having a factory finish misses some very important steps. A factory finish is applied in a “controlled” dust free environment, then a protective top coat is applied, and finally, the finish is oven cured for longevity, this cannot be accomplished finishing cabinets on site.

17. The local “custom” cabinetry maker builds his own cabinets, is this worth considering?

There are some very fine, smaller custom cabinetry makers across the country, but the majority of them are just building the “boxes”, then sourcing the doors and drawer headers from a third party which can lead to issues with finish discrepancies, extended lead times, and warranty issues down the road. There are also shops that are calling themselves “custom” that are doing nothing more than purchasing imported RTA (ready to assemble) cabinets, then “building” them and calling them “custom”, beware of either of these practices.

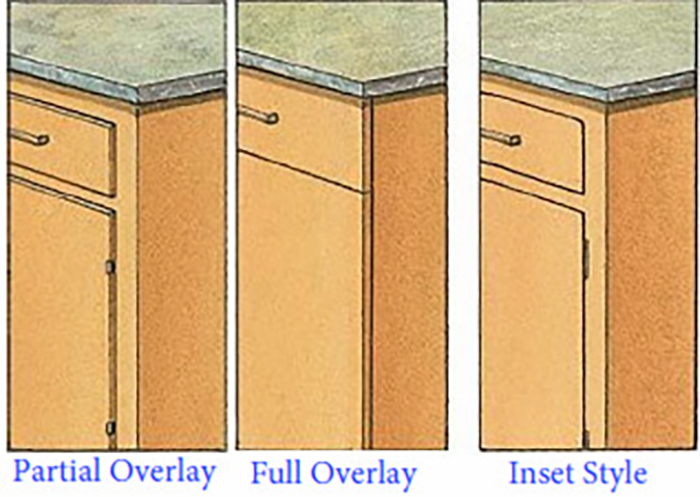

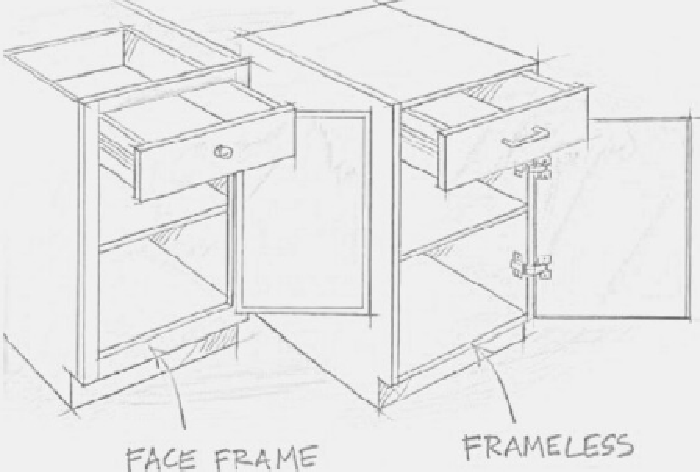

18. What is the difference between “face frame” and “frameless” cabinetry?

There are two different types of cabinet box construction. Face Frame (typical American style of cabinet construction, these can be “full overlay”, “partial overlay”, or “inset”) cabinet construction relies on a perimeter frame on the front of the cabinet box that the doors will be hinged off of. Frameless (also called “full access” or “European”) cabinet construction eliminates the frame, doors hinges are attached directly to the side of the cabinet box. CCD works with both types of construction and will help you determine which style best fits your project needs.

19. The cabinets we are looking at are called “RTA”, what does that mean?

Ready to assemble (also called “flat packed”) cabinets are typically imported cabinets. They are shipped this way to minimize the amount of space they occupy on a container ship. This may be viable with regard to shipping logistics, but not the style quality North American manufacturers will employ. Not only will the end user have to assemble their own cabinetry, but this also signifies a very “basic” cabinet line which may be fine for “filling” the space, but most CCD clients are shooting for more than that.

20. We are considering a very “contemporary” design style, does this matter to our designer?

This is a very important consideration that must be fully understood by your cabinet designer. A very contemporary design will require a different skill set than the designer that is typically working with more traditional designs. Ask for examples of high end, contemporary design finished projects your designer can share with you. At CCD, we have completed hundreds of very high end contemporary designs from coast to coast. Please visit our portfolio page to see some examples.

21. Should our designer be able to show us pictures of their completed projects?

YES! This should be a red flag if your designer cannot show examples of completed projects. It seems like most websites out there will have pictures on their portfolio page of the same “stock” photos that the manufacturers post on their sites. CCD’s portfolio is exclusively images of completed projects, not someone else’s work.

22. My design looked great on paper, but after installation we have functionality issues, why is that?

This is a common problem when working with an inexperienced designer. Most computer savvy people can manipulate a design in the design software, but if they do not truly understand how cabinetry works, there may be design errors. Examples may be not “pulling” a blind corner cabinet, moulding projection issues, traffic flow issues, missed design opportunities, etc. CCD employs only true professionals.

23. Why does my designer request so many room details, even the areas without cabinetry?

CCD will want to incorporate as many details in the design for numerous reasons, even the areas where you are not placing cabinetry. This will allow the designer to fully “capture” the space for you visually, but also will eliminate those design areas that may arise if the designer does not fully understand the space and floorplan.

24. What are “fillers”, and do I need them?

Yes, fillers are needed generally in all designs (sometimes in inset, we will eliminate, minimize depending on type of install). They provide the jobsite “leverage” (adjustment) needed to allow for proper door and drawer function as well as allowing the installer to “scribe” to fit as you may have a difference in the wall squareness v. the cabinetry squareness.

25. How do I adjust hinges?

26. How do I install cabinets?

As a CCD client, it is your installers or contractors responsibility to field verify all dimensions that are on the design. Your installer will want to do a “layout” of the proposed cabinetry prior to order placement to minimize the risk of receiving incorrect cabinetry which will cost them time and money awaiting replacements. CCD is not responsible for any over sites with regard to incorrectly submitted dimensions.